Project LAMBDA has reached a significant milestone with its successful demonstration at Circu Li-ion’s facility in Luxembourg, where an industrial Kuka robot disassembled high-voltage EV batteries using advanced AI-based tactile control. The system employed 3D vision, force feedback, and a neural network trained through reinforcement learning (RL) to precisely cut and remove a cable harness from a live EV battery pack. This cutting-edge approach ensures safety by eliminating the need for human operators in hazardous battery disassembly tasks.

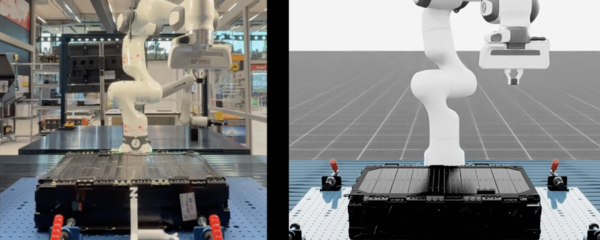

The breakthrough is the result of a close collaboration between AICA, Circu Li-ion, and the Swiss Battery Technology Center (SBTC). SBTC’s research focused on developing simulated environments and low-level control strategies, which allowed the robot to learn dexterous skills in a virtual setting before applying them in the real world. “Our mission at the SBTC is to de-risk and accelerate the adoption of new technologies for the battery industry,” explained Christian Ochsenbein, Head of SBTC. “By first conducting the foundational research and then validating the AI approach in our specialized labs, we built the confidence needed for our partners to deploy it in a live industrial setting."

AICA, the software integrator, played a crucial role in bridging the gap between research and real-world applications. Their adaptive control pipeline improved the realism of simulations and enabled the seamless deployment of RL-trained policies for real-time execution on industrial robots. “With the LAMBDA project, we've demonstrated a powerful and practical way to tackle that gap on real industrial robots, not just on fine-tuned research platforms. Our pipeline makes retraining and deploying new behaviors from simulation efficient and practical, marking a major step forward for more intelligent and flexible automation." said Enrico Eberhard, CTO at AICA.

This project pushes the boundaries of safe, scalable battery recycling, paving the way for further advancements in automation and robot learning for industrial applications.